A-PLUS Floor Guard Epoxy Floor Coating

Key Features:

- 100% Solids: Ensures a tough, smooth, and glossy finish.

- Self-levelling: Covers minor surface imperfections.

- Superior Durability and Adhesion: Resistant to abrasion, impact, and chemical spillage.

- Waterproof: Completely waterproof.

- Low Maintenance: Easy to clean.

- 1-Coat Application: Saves time and cost.

- Mixing Ratio: 3:1 paint to hardener.

- Pot Life: 30 minutes to 1 hour.

- Compressive Strength: 7000psi.

- Shelf Life: One year when stored in dry, cool conditions.

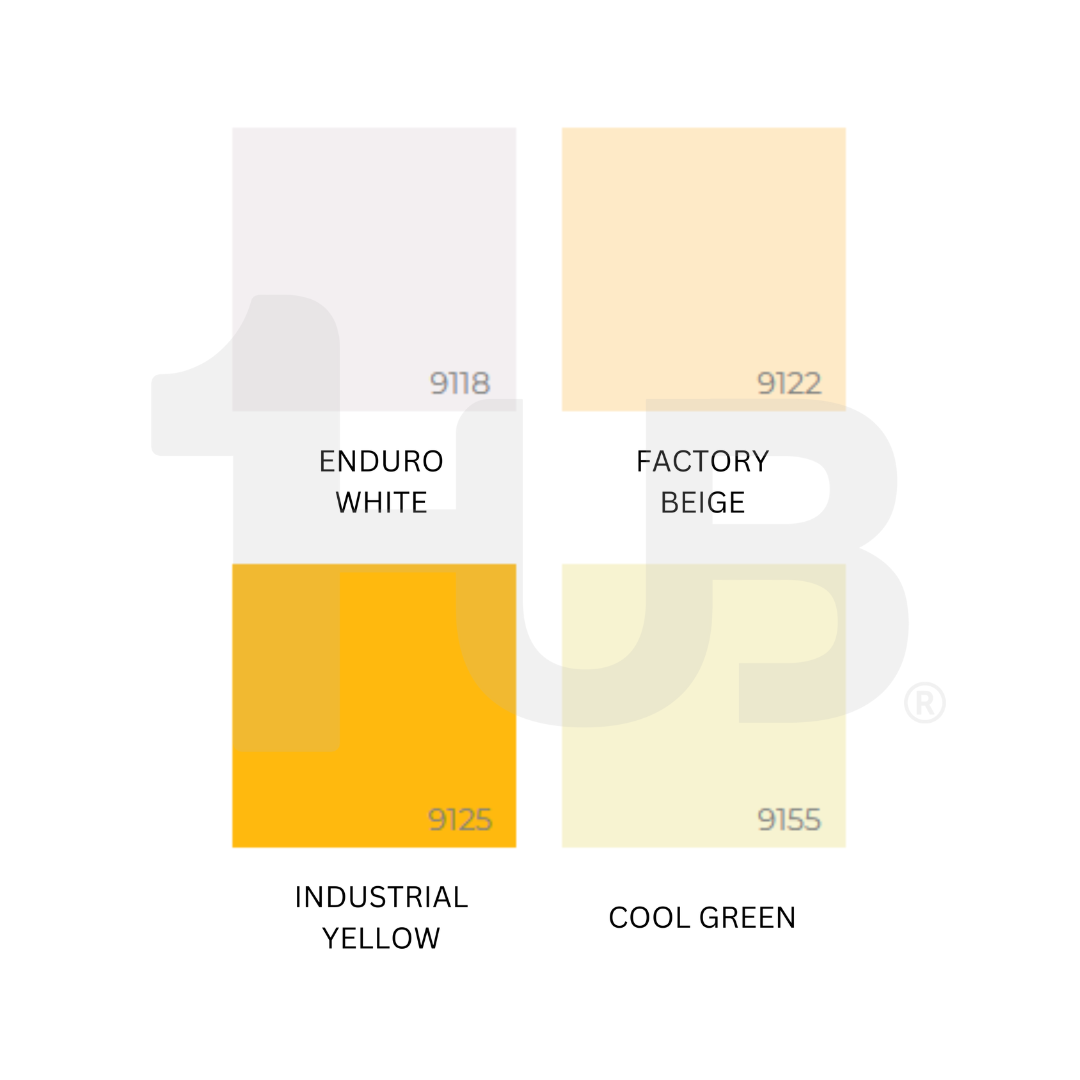

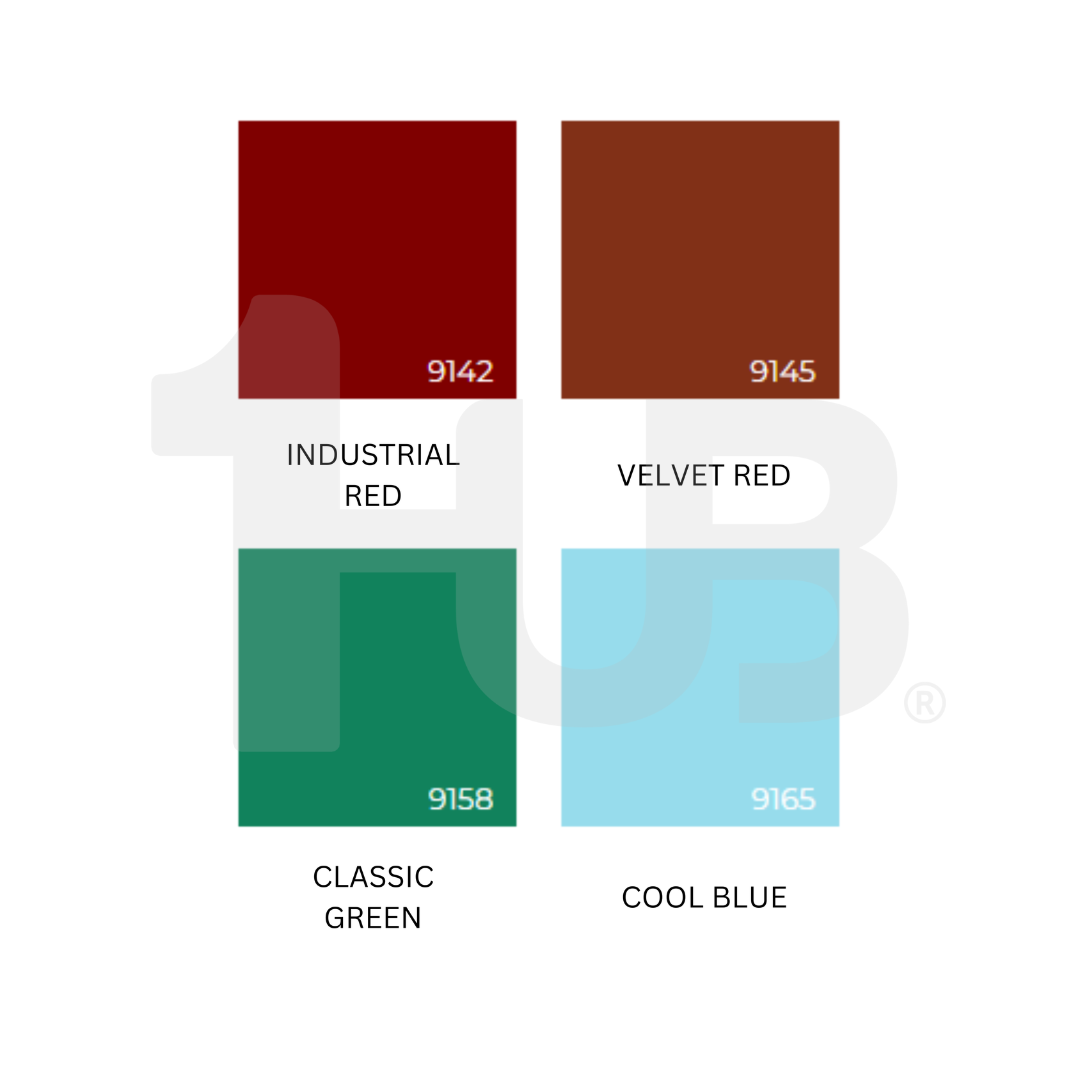

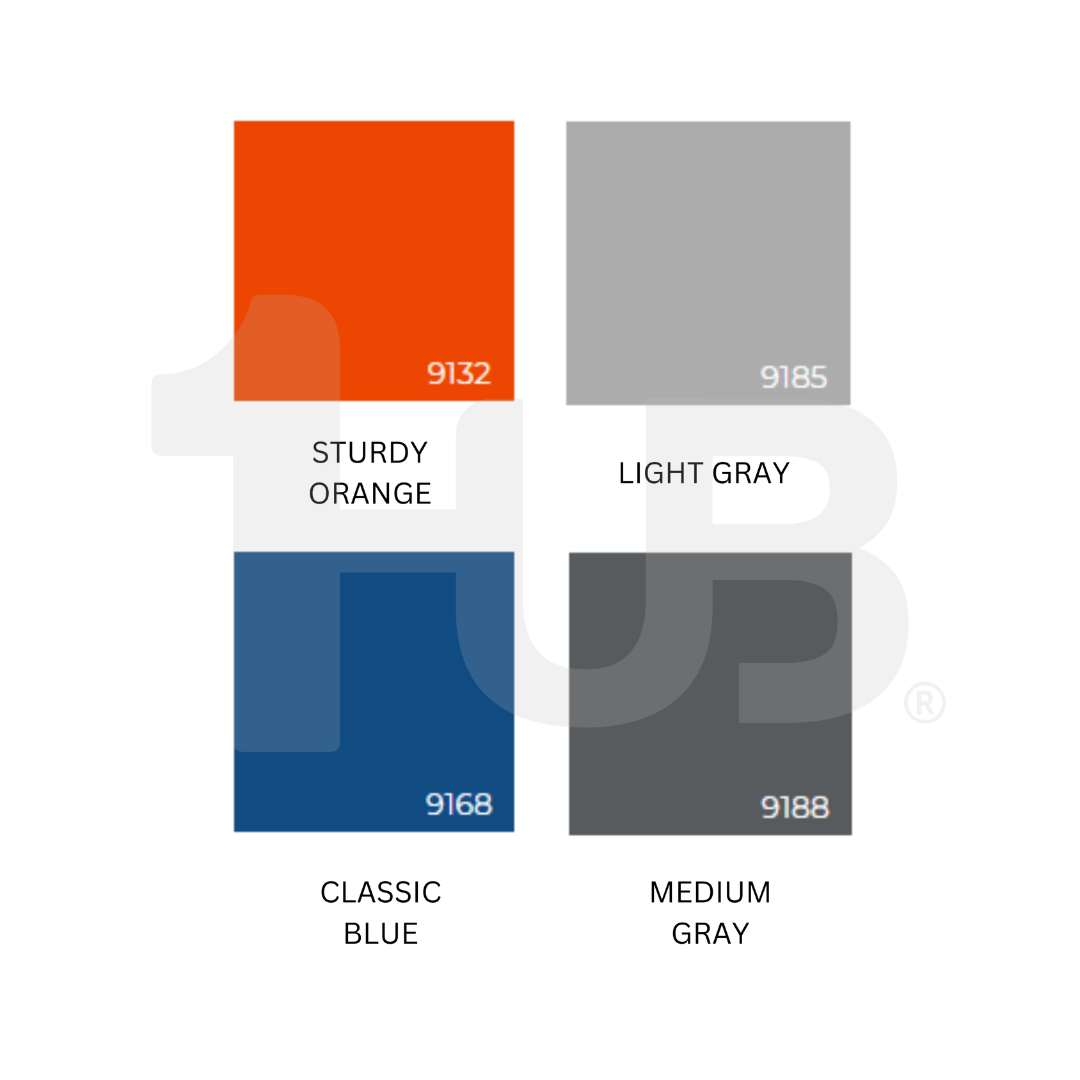

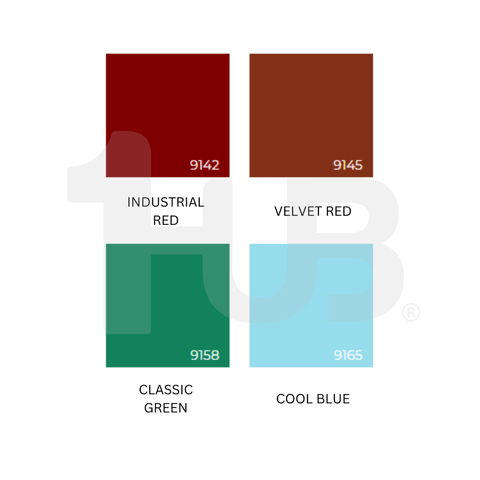

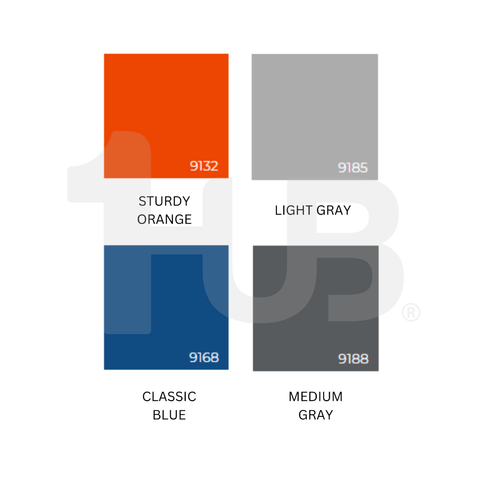

- Colors: Available in 12 factory mixed colors.

Applications:

- Indoor Concrete Floors: Ideal for warehouses, laboratories, food processing plants, residential buildings, indoor parking areas, and more.

- Steel Floors: Apply 1 coat of A-PLUS Floor Guard Epoxy Floor Coating using a v-notched trowel or squeegee.

- Concrete Floors (Plain Finish): Apply A-PLUS Floor Guard Concrete Sealer, then A-PLUS Floor Guard Epoxy Floor Coating.

- Concrete Floors (Non-Skid Finish): Apply A-PLUS Floor Guard Concrete Sealer, broadcast aggregates, then A-PLUS Floor Guard Epoxy Floor Coating.

Surface Curing Time:

- Light Traffic: Overnight.

- Heavy Traffic: 3-7 days.

Cleaning-Up Solvent: A-PLUS PG Epoxy Reducer.

Packaging: 4L set.

Application Tools:

- V-notched Trowel

- V-notched Squeegee

- Spiked Rollers

Principal Uses:

- Indoor concrete floors

- Heavy-duty areas: warehouses, groceries, laboratories, food processing plants, kitchens, garages, parking areas

Sheen: Gloss

Coverage:

- Sealer Coat: 25-30sqm per gallon

- Topcoat: 8-10 sqm per gallon @ 400-600 micrometers thickness

Surface Dry Time: 3 – 4 hours

Dry Through: Overnight for light traffic, 3-7 days for full strength.

Thinning: As supplied.

Clean-Up Solvent: A-PLUS PG Epoxy Reducer while paint has not yet hardened.