A-PLUS Sea Master Marine Enamel Paint

Product Overview: A-PLUS Sea Master Marine Epoxy Enamel Paint is a 2-component heavy-duty premium marine paint designed for demanding and harsh conditions experienced by vessels and structures in frequent contact with seawater. It provides a hard, glossy, high-build coating with superior resistance against saltwater, various chemicals, and corrosion.

Key Features:

- Premium 2-Component Epoxy-Based System: Ensures long-term protection against abrasion and rusting.

- High Solids Glossy Marine Coating: Offers superior durability, hardness, and adhesion.

- Excellent Resistance to Seawater, Chemicals, Oils: Provides outstanding protection against corrosion and degradation.

- Suitable for Various Materials: Adheres well to aluminum, fiberglass, steel, wood, and more.

- Lead-Free: Safe for marine life.

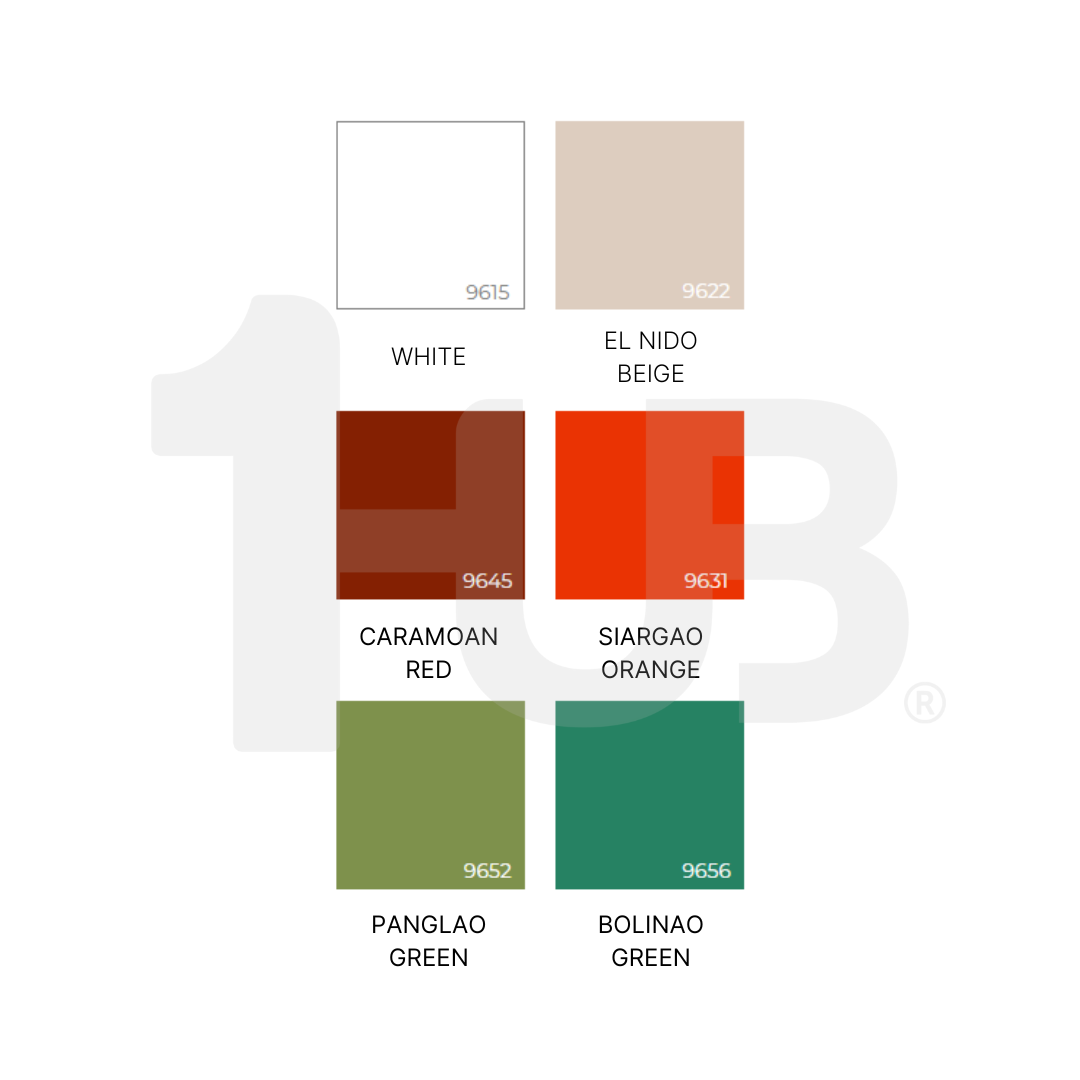

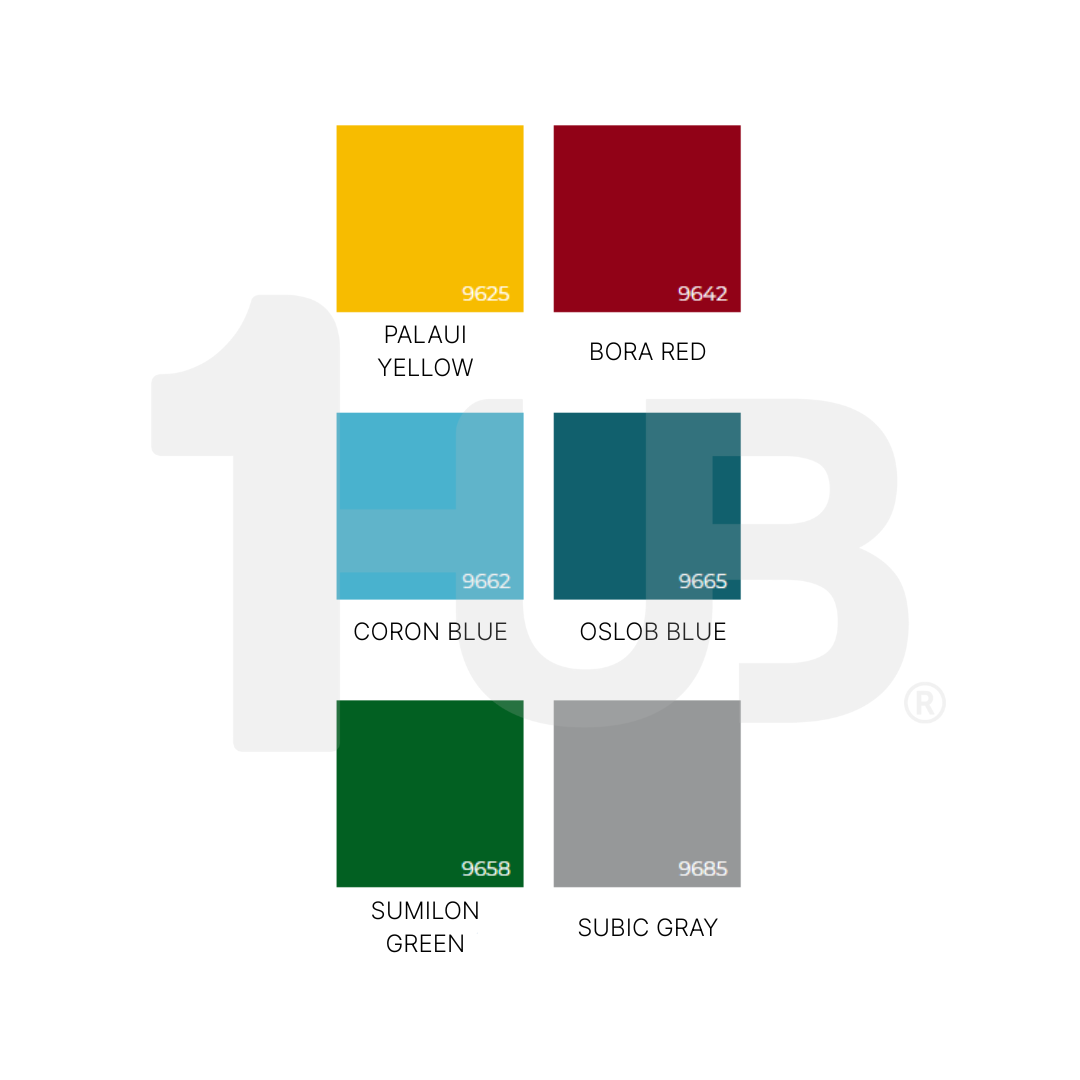

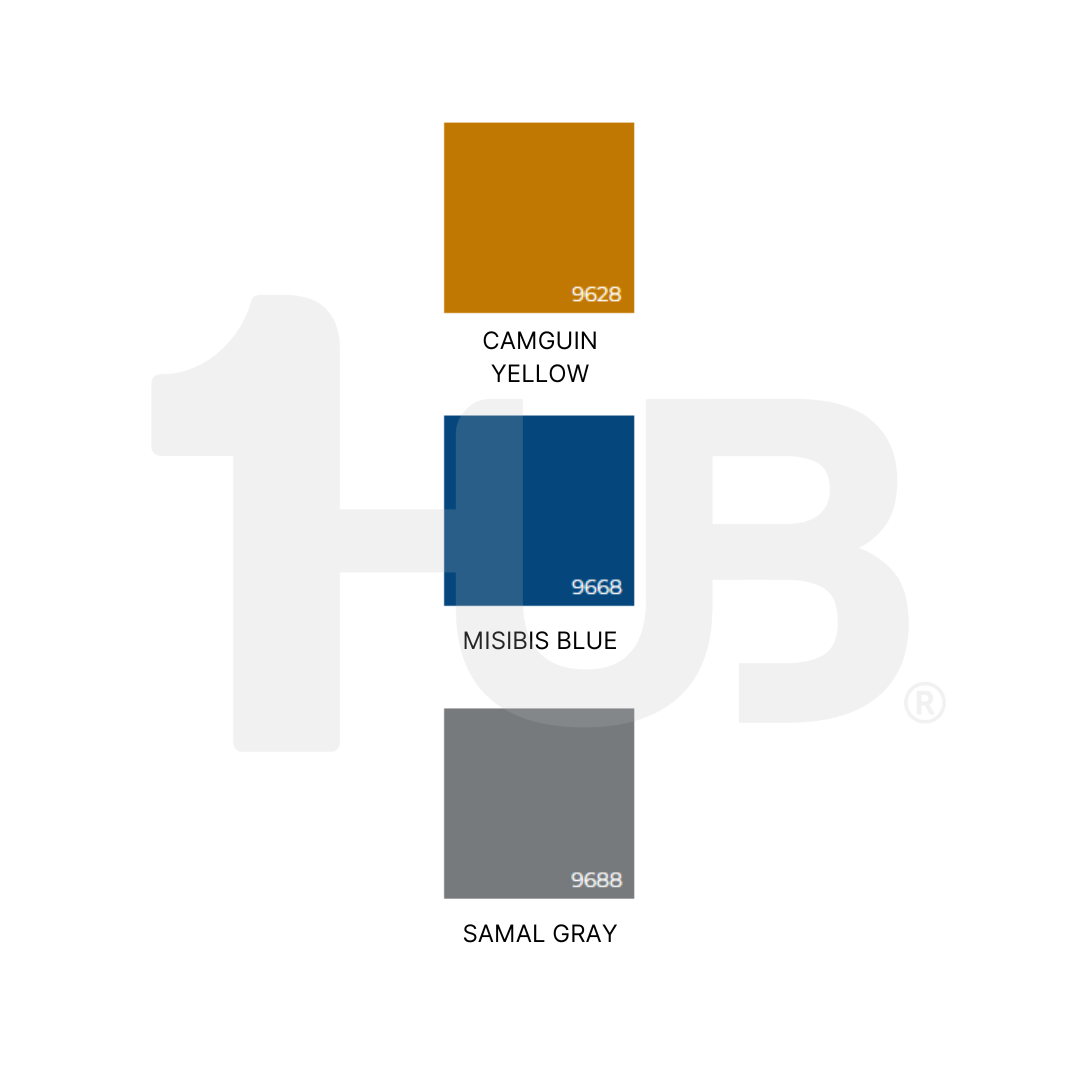

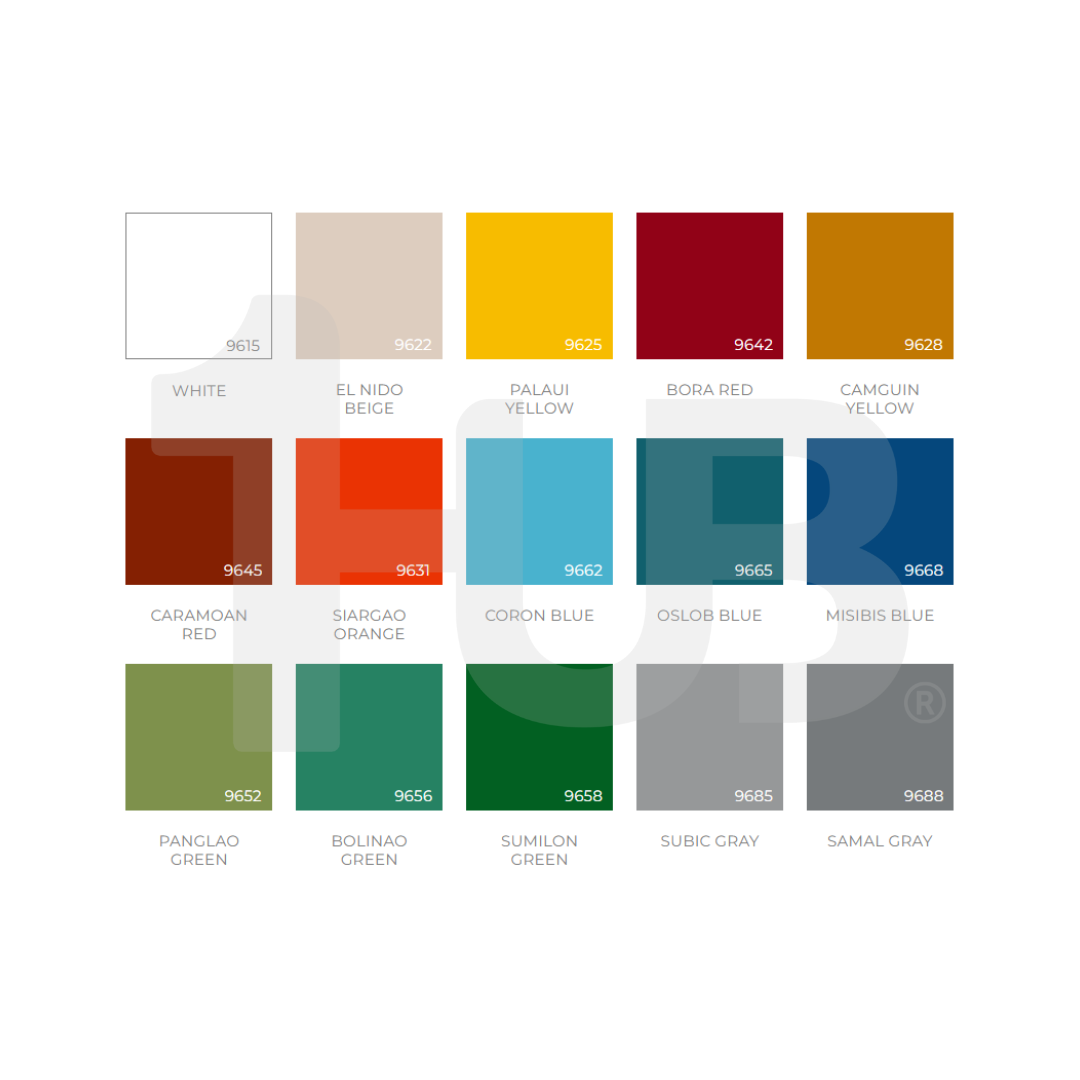

- Available in 15 Factory-Mixed Colors: Includes options like Black and White.

Application Instructions: 1. Primer: Observe proper surface preparation. Mix product well before applying at least 2 coats of A-PLUS Sea Master Marine Anti-Corrosive Epoxy Primer using a brush, roller, or spray. Allow at least 8 hours drying time before recoating. 2. Putty: Patch up minor surface imperfections with fully mixed components of A-PLUS A&B Heavy-Duty Marine Epoxy Adhesive. Sand lightly before proceeding with the topcoat. 3. Topcoat: Apply at least 2 coats of A-PLUS Sea Master Marine Epoxy Enamel Paint using a brush, roller, or spray.

Principal Uses:

- Exterior/Interior: Vessels, main decks, railings, hulls, masts, and other parts or surfaces of ships and structures made of aluminum, steel, wood, fiberglass, and more.

Sheen: Gloss

Coverage: 25-30 sqm per gallon / coat

Surface Dry: 6 – 8 hrs

Recoat Interval: 1 day

Dry Through: Cures overnight. Full strength at 3 days

Thinning: A-PLUS PG Epoxy Reducer

Clean-up Solvent: A-PLUS PG Epoxy Reducer

Application: Brush, Roller, Spray

Packaging: 4L

Also Available in: Black, White

Note: Ensure proper surface preparation and mix the product well before application. Allow adequate drying time before recoating.